|

|

|

|

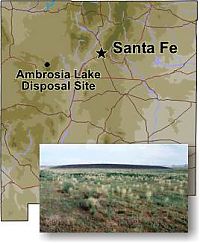

Ambrosia Lake (Phillips Petroleum) Mill

|

|

|

|

Location: The Phillips mill site is located in the Ambrosia Lake Valley about 25 miles north of Grants, New Mexico. It is one of two uranium mills that were operated in the valley. A total of five mills were built between December 1956 and December 1959 in the Ambrosia Lake district of the uranium mining area known as the Grants mineral belt, which extends from near Albuquerque, New Mexico, westward for about 100 miles across the southern margin of the San Juan Basin.

Background: Phillips Petroleum Company began construction of the mill in 1957, and it entered operation in mid 1958. The company had signed a contract with the U.S. Atomic Energy Commission (AEC) in September 1957 for a mill at Grants, New Mexico. The original mill site covered about 200 acres. Over time, about 570 additional acres were impacted by the spreading of radioactively contaminated debris from the mill tailings pile by wind and rainwater erosion. A conventional alkaline leach process was used at the mill from June 1958 to April 1963. During its operating years, the mill processed about 1,800 tons of ore per day that averaged 0.23 percent U3O8, and generated some 3 million tons of tailings. Ore for the mill came mainly from underground mines in the Ambrosia Lake district. United Nuclear Fuels Corporation (UNC) purchased the Phillips mill and uranium mine properties in February 1963, and the AEC uranium procurement contract with Phillips was transferred to UNC. In March 1963, ore processing at the Phillips mill was ended and the mill was closed by mid year. In June 1995, UNC arranged for toll milling of its ore at the nearby Homestake-Sapin mill in which UNC was a limited partner. About 400,000 tons of tailings materials from the Phillips mill site were eventually used by UNC for backfilling mines, and in early 1981 about 2.6 million tons of tailings-pile materials remained at the mill site. The tailings lie on unconsolidated valley fill material. A thick, impervious shale formation separates the tailings from the confined groundwater aquifers. Contamination of the aquifers by the tailings material is highly unlikely. The Phillips mill did not operate after March 1963, though it was maintained on a stand-by basis. From the mid 1970s until the Phillips mill site was permanently closed in 1982, a resin ion exchange (IX) plant to recover uranium from waste mine water was operated in the main mill building. This operation did not increase the size of the tailings pile stored at the mill site. The IX product was treated at the nearby United Nuclear-Homestake uranium mill at Grants, New Mexico.

16 files, last one added on Apr 30, 2006

Album viewed 517 times

|

|

|

|

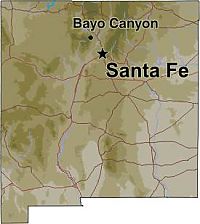

Bayo Canyon

|

|

|

|

Bayo Canyon (TA-10) Site

The Bayo Canyon Site, owned by Los Alamos County, is located in the Pajarito Plateau Region near Los Alamos, New Mexico. Los Alamos National Laboratory radiochemistry operations and explosives experiments conducted between 1943 and 1961 contaminated buildings, sewer lines, and soils at this site.

The U.S. Atomic Energy Commission remediated contaminated areas from 1960 to 1963. DOE implemented additional remedial action under FUSRAP in 1982 to prevent disturbance of contaminated subsurface soil that remains within a 1.5-acre area. DOE erected six permanent monuments to demarcate the contaminated area and restrict the use of this land by prohibiting excavation until the year 2142, when decay of the remaining residual radioactive material will allow the release of the affected area for unrestricted use.

Institutional controls at the site prevent excavation of contaminated subsurface soil. The governing authority and owner of the site, Los Alamos County, will maintain these controls. DOE does not require on-site monitoring or surveillance. Legacy management activities consist of managing site records and responding to stakeholder inquiries.

1 files, last one added on Oct 30, 2005

Album viewed 366 times

|

|

|

|

Belfield Ashing Facility

|

|

|

|

Location: The Belfield facility site is located about one mile southeast

of the town of Belfield in Stark County, North Dakota.

Background: Union Carbide Corporation (UCC) built and operated the facility in the early 1960s to burn uraniferous lignite coal. The plant had a capacity of 100 tons of ore per day and was operated from July 1965 to November 1967. The plant site was located near the mines to decrease the freight haulage costs. Burning the lignite concentrated the uranium values in the ash product that was directly amenable to further processing at the company’s Rifle, Colorado, uranium mill. The raw lignite ore, which contained 35-50 percent moisture by weight, was burned in a natural gas fired, rotary kiln to decompose and drive off the organic constituents and carbon. The kiln was 8 feet in diameter by 125 feet in length, and it operated at 1,300°F to 1,600°F depending on the lignite feed quality. The lignite ore averaged about 0.37 percent U3O8, and the uranium values were concentrated in the ash by the burning process. Uranium recovery in the ash product averaged 93 percent. During burn operations, ash dust from the kiln was collected by a wet scrubber and was returned to the rotary cooler/discharge unit where the hot ash emerged from the kiln. The original plant site covered about 11 acres. In 1980, a U.S. Department of Energy survey of the area showed that an additional 21 acres contiguous to the site were contaminated by low amounts of a wind-blown ash residue, apparently released during plant operations. The volume of contaminated soil at the site is estimated to be about 57,000 cubic yards. No clearly defined process-residue piles or waste ponds exist at the site Sludge-pit areas may possibly be buried at the site. The Belfield site is owned by private interests.

1 files, last one added on Jan 24, 2006

Album viewed 332 times

|

|

|

|

Bluewater, New Mexico

|

|

|

|

Uranium ore was processed at Bluewater, New Mexico,

from 1953 to 1982. These operations created processrelated

waste and tailings, a sandlike waste product

containing radioactive materials and other contaminants.

ARCO Coal Company (ARCO), the site licensee,

completed encapsulation of the tailings in two large

engineered disposal cells in 1995.

The U.S. Nuclear Regulatory Commission included the

Bluewater Disposal Cell under general license in 1997.

DOE is responsible, under the general license, for the

long-term custody, monitoring, and maintenance of the

site. The DOE Long-Term Surveillance and Maintenance

(LTSM) Program at the DOE Grand Junction (Colorado)

Office is responsible for the long-term safety and

integrity of the disposal site.

In 1988, DOE established the LTSM Program to provide

stewardship of disposal cells that contain low-level

radioactive material after completion of environmental

restoration activities. The mission of the LTSM Program

is to ensure that the disposal cells continue to prevent

release of contaminated materials to the environment.

These materials will remain potentially hazardous for

thousands of years. As long as the cells function as

designed, risks to human health and the environment

are negligible.

The LTSM Program maintains the safety and integrity

of the disposal cell through periodic monitoring,

inspections, and maintenance; serves as a point of

contact for stakeholders; and maintains an information

repository at the DOE Grand Junction Office for all sites

in the LTSM Program.

2 files, last one added on Oct 30, 2005

Album viewed 369 times

|

|

|

|

Bowman Ashing Facility

|

|

|

|

Location: The Bowman facility site is located about seven miles west of the town of Bowman in Bowman County, North Dakota

Background: Kerr-McGee Oil Industries, Inc., built the facility in late 1963 to convert uraniferous lignite (the raw ore) into a more economically handled form. The plant, operated from March 1964 to February 1967, burned lignite in three natural-gas fired, rotary kilns at a site near the mines to decrease the freight haulage costs. The burning process decomposed and drove off the organic constituents and carbon. The ore’s uranium and molybdenum values were upgraded about two times in the residual ash, which was then shipped by rail for final processing at the company’s Ambrosia Lake, New Mexico, mill. The kilns were 120 feet long by 7 feet in diameter and processed 80-90 tons of lignite ore per day. The raw lignite ore averaged 0.43 percent U3O8. Uranium recovery in the ash product averaged 88 percent. The Bowman plant site covered about 12 acres. At the facility site, radioactively contamination materials were found to locally extend to three feet below the surface. No clearly delineated process-residue pile or a waste pond exists at the site. An area of 59 acres has been contaminated by low amounts of wind-blown ash residues, apparently released during plant operations. It is estimated that about 100,000 cubic yards of low grade contaminated material are present at the site. The Bowman site is owned by private interests.

1 files, last one added on Jan 24, 2006

Album viewed 311 times

|

|

|

|

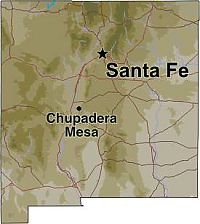

Chupadera Mesa

|

|

|

|

Approximately 28 miles northeast of the Trinity atomic bomb test site on the White Sands Missile Range , Northeast of Bingham , New Mexico

The Chupadera Mesa Site is privately owned land northeast of the White Sands Missile Range and the city of Bingham in New Mexico. The site was in the fallout zone of the first nuclear weapons test, the Trinity test, conducted on July 16, 1945. The test was part of the Manhattan Project that was established during World War II to conduct research for the development and production of nuclear weapons.

The U.S. Atomic Energy Commission and successor organizations monitored the site between 1945 and 1985. In 1986, DOE determined that residual radioactive materials met applicable standards, did not require remediation under FUSRAP, and released the site for unconditional use.

No supplemental limits or institutional controls are in effect at the site, and DOE does not require on-site monitoring or surveillance. Legacy management activities consist of managing site records and responding to stakeholder inquiries.

1 files, last one added on Oct 30, 2005

Album viewed 339 times

|

|

|

|

|

|

|

|

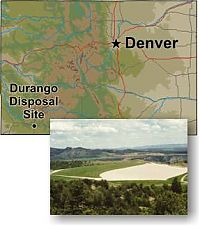

Durango Mill

|

|

|

|

Location: The Durango mill site is located just southwest of Durango in La Plata County, Colorado.

Background: From 1880 to 1930 the American Smelting and Refining Company operated a lead smelter at the Durango site adjacent to the Animas River. At the beginning of World War II, the Reconstruction Finance Corporation (RFC), a Federal agency, acquired the smelter facility. RFC contracted with U.S. Vanadium Corporation to convert the facility to produce vanadium for Metals Reserve Company, which purchased strategic-materials for the Government during the war. In 1943-1944, U.S. Vanadium also operated a uranium-vanadium sludge plant at the site to process old vanadium mill tailings under contract with the Manhattan Engineer District. (The sludge was treated at U.S. Vanadium’s Grand Junction, Colorado, refinery where vanadium was removed and uranium was produced as black oxide.) The Durango mill produced vanadium until early 1944, when, with adequate vanadium stocks, Federal purchasing ended. At that time, U.S. Vanadium Corporation purchased the facility from RFC, and it continued to produce vanadium for commercial sales until the mill closed in August 1945.

The U.S. Atomic Energy Commission (AEC) purchased the 147-acre Durango mill site from U.S. Vanadium Corporation in 1948. Later that year, AEC leased the facility to Vanadium Corporation of America (VCA) with an option to purchase the plant at the end of the first lease period (1953). In late 1948, the first of three AEC uranium procurement contracts was signed with VCA. In 1949, production of uranium concentrates for sale to AEC began. Milling capacity was increased from 175 tons of ore per day (TPD) in 1953 to 750 TPD in 1958. From 1949-1963, mill throughput averaged about 350 TPD, and about 1.6 million tons of ore averaging 0.29 percent U3O8 and 1.55 percent V2O5 were processed. In 1953, VCA exercised its option to purchase the facility, and afterward the mill was operated as a private facility. VCA shut down the mill in March 1963, and it was later dismantled.

Ore for the mill came from numerous small mines in the Four-Corners area of Arizona, Colorado, New Mexico, and Utah. The plant also processed the uranium concentrate product from the Monument Valley, Arizona, upgraded facility; slime concentrates from the Naturita, Colorado, plant; and vanadium liquors bought from other producers. Uranium recovery averaged 80 percent and vanadium 70 percent from the combined mill feed. From 1949-1963, AEC purchased all of the mill's U3O8 production and its V2O5 production in excess of commercial demand. At the mill site, two tailings piles and one raffinate (milling process liquids) pond covering about 25 acres remained at the site before cleanup.

10 files, last one added on Jan 24, 2006

Album viewed 392 times

|

|

|

Edgemont Mill

|

|

|

|

Location: The former mill site mill is located immediately east of Edgemont, Fall River County in southwestern South Dakota.

Background: Sandstone-type uranium ores were discovered in the Black Hills area north of Edgemont, South Dakota, in mid 1951 and north of Carlile, Wyoming, in early 1952. Exploration by the Government and private firms developed sufficient ore reserves by 1955 to justify a mill. Mines Development, Inc. (MDI), began construction of the uranium mill in 1955 on a site adjacent to an ore buying station operated by the U.S. Atomic Energy Commission (AEC). At startup in July 1956, the mill’s initial throughput capacity was 250 tons of ore per day (TPD); this was increased to 500 TPD by mid 1957. In early 1955, MDI had contracted to produce uranium for the AEC, and the mill supplied uranium under additional contracts through December 1968. In July 1956, MDI purchased the AEC ore buying station with its accumulated stockpile of uranium ore. From 1956 to 1960, the mill did not recover vanadium (from the carnotite-type ore), and vanadium slime tailings from the mill were impounded in a pond separate from the mill’s coarse tailings pond. In 1960 and afterward, MDI recovered both uranium and vanadium. Recovery of other metals at the mill was unimportant. During the period of AEC deliveries, about 500 TPD of ore averaging 0.20 percent U3O8 was processed, and the total of ore treated was more than 1.6 million tons. About 99 percent of the uranium production in that period was purchased by the Government. All of the vanadium production was sold in the commercial market. From 1969 to 1974, the mill produced uranium and vanadium for commercial market sales. The old vanadium slime tailings also were reprocessed beginning in 1972 for their vanadium values. In mid 1974, the Tennessee Valley Authority (TVA) acquired the mill site and plant from Susquehanna-Western, Inc., parent firm of MDI, along with rights to several uranium properties. TVA, based on economic and other factors, decided to not restart the mill. It permanently closed the mill in August 1974.

Ore feed for the mill, which operated mainly as a “custom” mill, came largely from independently operated mines in the Black Hills area of South Dakota and Wyoming. Carnotite-type ores (shallower, oxidized zone) and uraninite-coffinite ores (deeper, reduced zone), were the primary uranium minerals. In the early years, some ore was shipped from mines in the Powder River Basin area of Wyoming and from Washington State, and uraniferous ash from open-field burning of lignite ore was also fed to the mill. At first, the burning of lignite ore was done in the mining area near Slim Buttes, South Dakota. Later, stockpiled lignite ore was shipped to the Edgemont mill site and burned there in linear heap piles.

10 files, last one added on Jan 24, 2006

Album viewed 355 times

|

|

|

Elk River

|

|

|

|

Elk River Station is an incinerator operating in Elk River, Minnesota that generates 35 to 42 megawatts of electrical power. The site was originally built as a coal and oil-fired facility in 1950, then was converted to a nuclear power plant (boiling water reactor) in 1963. The nuclear reactor was small and only operated from 1964 until 1968 before undergoing decommission and dismantlement in the following years, ending in the early 1970s. It resumed operating on coal and oil in 1968. In 1989, the facility was again converted, this time to use garbage for fuel. Waste arrives from Anoka, Benton, Hennepin, Sherburne, and Stearns counties, and the ash remaining after incineration is taken to a landfill in Becker, Minnesota. Elk River Station is operated by the Great River Energy cooperative.

2 files, last one added on Dec 12, 2005

Album viewed 426 times

|

|

|

|

|

Falls City Mill & Disposal Site

|

|

|

|

Location: The mill site is located about 8 miles southwest of Falls City in Karnes County, Texas.

Background: Uranium discoveries were made in southwestern Karnes County, Texas, in 1954-55. The early finds, shallow small deposits behind sandstone outcrops, were too small to support the long haulage distance to the nearest mill in northwestern New Mexico. From January 1960 to May 1961, the U.S. Atomic Energy Commission (AEC) operated a uranium-ore buying station in western Karnes County near the uranium deposits and it stockpiled some 111,000 tons of ore that assayed 0.19 percent U3O8. In July 1960, Susquehanna-Western, Inc., (SWI) entered into a contract to produce uranium for sale to the AEC, and these sales continued over the period 1960-1968 under two such contracts. SWI began construction in 1960 of a sulfuric acid leach mill on a site that originally covered about 1,600 acres. The mill was placed in operation in April 1961 with an initial capacity of 220 tons of ore per day (TPD) throughput, and it was expanded by 1969 to 1,000 TPD. Mill feed came largely from company-owned mines developed in ore deposits located relatively near the mill site in the central coastal plain area in south Texas. Over the period 1961-1964, all the ore that had been purchased at the AEC’s ore-buying station was sold to SWI for processing at the Falls City mill. A total of about 1.2 million tons of ore that averaged 0.19 percent U3O8 was processed during the period of AEC contracts (1961-1968). About 95 percent of the uranium was recovered from the ore. Of the uranium concentrate produced in those years, 31 percent was sold to the AEC and 61 percent was sold commercially. After expiration of the AEC contracts, the mill continued to produce uranium for commercial sales until it was closed in 1973. In the late 1970s, Solution Engineering, Inc., acquired about 200 acres of the Falls City mill site, including the mill and four of the nearby tailings piles. Between 1978-1982, Solution Engineering, under a license from the State of Texas, used a solution mining process to produce a relatively small quantity of uranium concentrate from the in-place tailings piles.

When milling of uranium ore was ended in 1973, the mill tailings were stored in 7 impoundments: there were 6 tailings piles (four were located in unlined mined-out pits) and one pond contaminated with tailings and mill residues. These covered an area of about 146 acres on the original mill site. In 1982, the pond liquids were evaporated and all the tailings piles were stabilized by a 1.5-foot thick earthen cap that was seeded to establish an erosion-resistant vegetative cover.

7 files, last one added on Jan 24, 2006

Album viewed 420 times

|

|

|

|

|

|

|

Grand Junction (Climax Uranium) Mill

|

|

|

|

Location: The Grand Junction (Climax Uranium) mill site is located in the City of Grand Junction, Mesa County, Colorado.

Background: In 1950, the Climax Uranium Company signed a uranium concentrate purchase contract with the U.S. Atomic Energy Commission (AEC) for a uranium mill located at Grand Junction, Colorado. The mill was located on a 200-acre tract on the north bank of the Colorado River in an industrial area of the city. This mill was the first in the United States built primarily for uranium production with secondary vanadium production. The mill (Grand Junction Mill 1 under UMTRA) began operation in 1951 and produced uranium for sale to the AEC under two contracts through December 1966. The mill was designed for a throughput capacity of 100 tons of ore per day (TPD); it was increased to 500 TPD by 1955. In its early years, the mill used the newly developed acid-leach/uranous phosphate precipitation process that, in pilot scale, yielded a high-grade uranium cake (concentrate) product. In full-scale operations, however, the cake product was of lower than expected grade. In 1956, uranium precipitation was changed to a hydrogen-peroxide process, and afterwards the mill produced a high-purity uranium cake product. Climax also changed to a solution-extraction process for uranium-vanadium separation about that time. The mill feed consisted of carnotite-type ores from a large number of mines in the Uravan mineral belt area of western Colorado. During the AEC contract years, the mill processed about 1.8 million tons of ore that averaged 0.28 percent U3O8 and 1.35 percent V2O5. During periods when the vanadium market was soft from mid 1957 to mid 1959, the mill’s production of vanadium in excess of commercial sales was also purchased by AEC. Climax’s last AEC uranium-procurement contract expired at yearend 1966, and afterward the mill continued to produce uranium and vanadium for the commercial market. The mill was permanently closed in March 1970. During the post-AEC years, the mill treated about 0.5 million tons of ore that averaged 0.26 percent U3O8 and 1.63 percent V2O5. In 1970-1971,Climax dismantled most of the mill, and equipment that could be decontaminated was sold. The tailings pile was contoured, covered with top soil, and seeded to establish a cover of vegetation. Over the mill’s lifetime, 1951 to 1970, nearly 2.3 million tons of ore were treated and about 11.7 million pounds U3O8 and 46.1 million pounds V2O5 were produced.

In the early1970s, an industrial park was established on an 85-acre parcel of the Climax mill site. A 40-acre tract was ceded to the State of Colorado. A 10-acre tract became private property.

In the 1950s and 1960s, uranium mill tailings from the Climax mill had been made available to the public. An estimated 300,000 tons of tailings were ultimately used in construction as a sand substitute or for backfill material at various sites throughout the Grand Junction and Mesa County area. These sites later became known as "vicinity properties." In 1972, Congress passed Public Law 92-314 (amended by P.L. 95-238) to provide funding and authority for a Federal/State program to perform remedial action on Grand Junction sites where uranium mill tailings were used, including private residences, schools, churches, and commercial locations. Relocation of tailings under the Federal program began in 1973, and the excavated materials were temporarily stored on the 40-acre State-held tract pending final burial. Under this cooperative program with the State of Colorado, the Government was responsible for 75 percent and the State 25 percent of the remediation cost.

1 files, last one added on Jan 23, 2006

Album viewed 423 times

|

|

|

Green River Concentrator

|

|

|

|

Location: The Green River concentrator site is located in Grand County, Utah, and about one-half mile east of the Green River, one mile southeast of the City of Green River, Emery County, Utah.1

Background: The Green River concentrator was built by Union Carbide Corporation (UCC) in early 1958 and was operated from March of that year to January 1961. The original site covered about 80 acres. The plant shipped uranium concentrate and carbon concentrate products by rail to the UCC uranium mill at Rifle, Colorado, for final processing. Feed to the Green River concentrator plant consisted of sandstone-type ore that contained between 0.27 and 0.30 percent U3O8. The ore was poorly cemented with clay and asphaltic materials, and part of the uranium was contained in the carbonaceous fraction. The carbonaceous fraction was recovered separately by screening and flotation of the ground ore. The flotation product was stockpiled for later treatment. (Removing the carbonaceous fraction was necessary to prevent problems in processing the Green River product at the Rifle, Colorado, mill.) The remaining ground, coarse-ore fraction was mixed with recirculated acid solution and a sand-slimer separation was then made on this slurry. The sand fraction was then acid leached, and uranium was precipitated from the pregnant solution. The precipitate was mixed with the remainder of the primary slimes, and that product was dewatered, dried, and shipped to the Rifle mill. The concentrator processed uranium ore at an average rate of about 200 tons per day (TPD). Over the concentrator’s operating life, a total of some183,400 tons of ore averaging 0.26 percent U3O8 was processed. The concentrator also recovered vanadium from the ore, which averaged about 1.00 percent V2O5. Recovery of U3O8 averaged 87 percent; data for vanadium recovery are not available. Ore for the concentrator came primarily from mines in the Temple Mountain area of the San Rafael Swell and Green River districts in Emery County, Utah. Some 137,000 tons of tailings were generated by the concentrator over its operating life. Later, a flash flood swept away about 14,000 tons from the tailings pile, and in 1982 the pile was estimated to contain about 123,000 tons of tailings. After the concentrator was closed down, the 9-acre tailings pile was stabilized with a 6-inch thick earthen cover. An onsite pond was positioned to collect surface rainwater runoff from the pile. Later, buildings remaining at the site were used by the U.S. Army’s Utah Launch Complex of the White Sands Missile Range in New Mexico. The State of Utah acquired the concentrator plant site from UCC in 1988.

1 files, last one added on Jan 24, 2006

Album viewed 344 times

|

|

|

Gunnison Mill

|

|

|

|

Location: The Gunnison uranium mill site is located just southwest of the City of Gunnison in Gunnison County, Colorado.

Background: In 1954-1955, uranium deposits were discovered in the Cochetopa, Tallahassee Creek, and Marshall Pass uranium districts in the Southern Rocky Mountains of central Colorado. Development of the deposits soon followed. In November 1956, the Atomic Energy Commission (AEC) signed a contract with the Gunnison Mining Company (GMC) for a small uranium mill at Gunnison, Colorado. The mill was built on a 62-acre tract just south of Gunnison, and its first delivery under GMC’s only contract was made in February 1958. In late 1961, GMC’s assets were acquired by Kermac Nuclear Fuels Corporation (KNF). The mill continued to operate under KNF until April 1962, when it was closed down. Originally designed for a throughput capacity of 200 tons of ore per day (TPD), the mill was operated over its life at an average of 350 TPD, due to the lower than anticipated grade of ore received. Ore deliveries in 1958 averaged 0.24 percent U3O8, but the grade declined to about 0.12 percent during 1960-1962. The mill feed consisted mainly of uraninite in silicified and brecciated elastic rocks and came mainly from company mines in the Cochetopa district, but a small amount of ore was purchased from independent miners. From January 1958 to April 1962, the mill processed about 540,400 tons of ore that averaged 0.15 percent U3O8 and recovered 1.45 million pounds U3O8 in concentrate. All concentrate production was sold to the AEC. Uranium was leached from the ground ore using sulfuric acid and sodium chlorate as the oxidant. A four-stage classifier-thickner circuit then separated the pregnant solution from the washed solids, which were sent to tailings. Uranium was concentrated from the pregnant solution using solvent extraction. Sodium carbonate solution was then used to strip the uranium from the solvent. This alkaline stripping formed an iron precipitate that was filtered from the solution and saved as an iron cake. From the clarified solution, uranium was precipitated and filtered. The final yellow cake product was dried and packed for shipment to the AEC’s Grand Junction, Colorado facility. After the mill was closed, the 39-acre, partially filled, tailings impoundment pond was reclaimed in accordance with plans approved by the Colorado Department of Health: the pond area was contoured, covered with soil material from a local gravel pit, and was planted with a mixture of grasses. A narrow, 3.5-acre parcel of the mill property was deeded to Gunnison County in 1966 for use in expanding the local airport facility. After 1964, several different owners held the remaining mill site property. In 1990, the mill site was acquired by the State of Colorado, which later assigned site ownership to Gunnison County.

1 files, last one added on Jan 24, 2006

Album viewed 363 times

|

|

|

|

|

|

|

|

|

|

|

|

|

Lakeview Mill

|

|

|

|

Location: The Lakeview mill site is located about one mile northwest of the City of Lakeview in Lake County, Oregon, and immediately west of U.S. 395. It is in a broad valley north of Goose Lake.

Background: Uranium deposits were discovered in south-central Oregon in the mid 1950s within the Basin and Range geological province. The deposits appear to be remnants of what possibly were once more extensive mineralized zones in essentially flat-lying host rock strata. The deposits possibly were formed by low temperature/low pressure hydrothermal action in an intensely altered tuffaceous host rock capped by a nonporous clay layer. The host rock occurs in a thick sequence of pyroclastic rocks, volcanic sediments, and lake-bed sediments interspersed with andesitic volcanic flows of Pliocene-age. Individual ore deposits are up to 150 feet in thickness, and ore was explored to a depth of 600 feet below the surface. Shallow ore consists principally of secondary uranium minerals and the deeper ore of coffinite associated with base-metal sulfide minerals. Steeply dipping and cross-cutting normal faults have cut the ore-bearing Pliocene sequence into large blocks that are displaced and tilted. It is thought that some faults were possible channels for emplacement of the uranium mineralization.

The first uranium ore production occurred in 1955 during initial development of the White King and Lucky Lass mines, which are located about 12 miles northwest of Lakeview mill site. Other uranium deposits were subsequently discovered in the area. In November 1957, the U.S. Atomic Energy Commission (AEC) entered a contract with the Lakeview Mining Company for a uranium processing mill at Lakeview, Oregon. The contract period extended through November 1963. The mill was constructed during 1958, and the first delivery of U3O8 to the AEC occurred in January 1959. The design of the Lakeview mill was similar to that of the uranium mill at Gunnison, Colorado, but included changes in its circuitry in order to treat the Lakeview district ores that contain uranium-arsenate and molybdenum-, antimony-, and other sulfide minerals. The milling process used sulfuric acid leaching of the ore and solvent extraction with an amine solvent to treat the leach liquor that had unusually high molybdenum content. Some of the ore also contained bentonitic clay that caused excessive frothing during ore processing and lowered uranium recovery. The mill’s rated capacity was 210 tons of ore per day (TPD), though the availability of ore varied and the actual amounts of ore processed ranged from 50 to about 400 TPD. In addition to ore produced from the two company-owned mines, about 15 percent of the ore processed at Lakeview was purchased from independent mine operators. After operating for only two years, the mill was closed in November 1960 due to a lack of ore. During that period, the grade of ore fed to the mill decreased from 0.20 percent U3O8 at startup in 1959 to about 0.09 percent when the mill was closed in 1960. A total of 131,355 tons of ore averaging 0.15 percent U3O8 was treated at the mill. Uranium recovery averaged 87 percent, and the total production, 342,259 pounds U3O8, was sold to the AEC.

In 1961, Kerr-McGee Oil Industries, through its subsidiary Kermac Fuel Corporation, acquired the assets of both the Lakeview Mining Company and the Gunnison Mining Company (Gunnison, Colorado). At that time, the Lakeview mill-site property consisted of 258 acres and contained the 30 acre tailings pile, which contained about 130,000 tons of tailings material that averaged about 3.7 feet in depth. The tailings impoundment utilized a natural clay liner and was surrounded by an earthen embankment. Six evaporation ponds covered about 65 acres of the original site, and the mill and supporting structures occupied about 12 acres. Between 1960 and 1968, the property had five owners. Atlantic Richfield Company (ARCO) acquired the Lakeview mill property in 1968. Under ARCO-sponsored site decontamination work, most of the contaminated materials were incorporated into the tailings pile, which was then stabilized with an 18-24 inch thick earthen cover. The mill building and other structures, emptied of useable machinery, remained at the site. Investigations of the mill site in 1976 found localized areas of elevated radioactivity and suspected contaminated-material burial sites. No evidence was found of windblown contamination from the mill site and no off-site usage of mill tailings was found. Additional removal/relocation of contaminated soil to the tailings pile during 1977 brought the mill site into compliance with the then-current Oregon State environment regulations. In March 1978, the property was purchased for use as lumber mill site.

4 files, last one added on Jan 24, 2006

Album viewed 354 times

|

|

|

|

|

|

Lowman Mill and Disposal Site

|

|

|

|

Location: The Lowman mill site is in north-central Boise County, Idaho, about 73 miles northeast of the City of Boise. It is in the Boise National Forest one-half mile northeast of the village of Lowman (on State Road 21).

Background: The Idaho batholith igneous complex extends about 300 miles N-S by 50 to 100 miles E-W in southwestern Idaho. It is comprised mainly of large intrusive bodies of medium to coarse-grained granite, quartz monzonite, and granodiorite. Pegmatite dikes are common in the granites. In this terrain, stream gravels and higher bench gravels contain placer deposits composed primarily of resistant, heavy-mineral grains (black sand) that were released from the batholithic rocks by weathering (decomposition and erosion). Placer deposits that formed in valleys that drain weathered quartz-monzonite outcrops contain a higher percentage of thorium-bearing minerals. These placers were mined for monazite (a thorium-bearing mineral) in the period 1903-1910 and again in the late 1940s. The thoria content of Idaho monazite is reported to be somewhat lower than other available commercial monazite concentrate. In the Bear Valley drainage of southern Valley County, Idaho, some placers contain monazite along with uranium-bearing mineral grain. These placers were mined for uranium, thorium, and rare earths from 1955 to1960. Common heavy mineral grains in the placers are ilmenite, magnetite, and garnet with lesser amounts of the uranium- and rare-earth minerals columbite, euxenite, and monazite and minor amounts of other opaque, radioactive, rare-earth minerals. The valley-fill sequence that contains these placer deposits consists of several layers of fine to coarse sand, clay, and gravel. The sequence averages less than 50 feet in thickness, though thicknesses of up to about 100 feet are reported.

The extent of the radioactive heavy-mineral placer deposits in Bear Valley was studied in a Government sponsored drilled program in the 1950s. The results indicated that while the placer deposits contain substantial tonnages of the uranium-bearing minerals, the mineral content of the placer deposits varies strongly and some contain relatively low amounts of uranium-bearing mineral grains. Most of the Bear Valley placer deposits sampled were found to contain generally low amounts of residual euxenite grains, making most non-commercial at that time.

At one locality in upper Bear Valley in the late 1950s, placers that contained euxenite as the predominant radioactive mineral were mined for uranium, rare earths, and associated heavy-mineral products. The mining operations consisted of dredging and jigging the raw placer material to wash and mechanically separate out the valued heavy-mineral black-sand fraction. About 8,500 cubic yards of stream gravels per day were recovered using two dredges. The amount of black-sand concentrate recovered per cubic yard of dredged raw gravel ranged between 45 to 140 pounds. The black-sand jig concentrate was transported to the Lowman mill site for further upgrading.

2 files, last one added on Jan 24, 2006

Album viewed 347 times

|

|

|

Maybell Mill

|

|

|

|

Location: The Maybell uranium mill site is located 5 miles northeast of the town of Maybell in Moffat County, Colorado.

Background: In November 1953, privately funded airborne radiometric surveying located anomalies over outcrops of fluvial sandstone strata of Miocene age near Maybell, Colorado. Only a few weeks earlier, radioactive outcrops had been located in similar strata near Baggs, Wyoming, during U.S. Geological Survey geological reconnaissance/radiometric surveying conducted for the U.S. Atomic Energy Commission (AEC). By March 1954, follow-up private airborne surveys, surface prospecting, and subsequent drilling had defined economic sandstone-type uranium deposits near Maybell. In August 1955, the AEC entered into a contract with the Trace Elements Corporation (TEC) for a uranium mill at Maybell, Colorado. TEC established a pilot-scale, ore-processing plant for test extractions and recovered 238 pounds of uranium concentrate, which the AEC purchased under the initial contract. In November 1956, the initial contract was superceded by a new AEC contract for a full-scale uranium mill near Maybell. Over the next year, TEC built the mill on an 84-acre tract near the uranium deposits. In late 1957, before the mill was placed in operation, TEC became a subsidiary of Union Carbide Corporation (UCC, later UMETCO), which assumed control of the operations. The first delivery of concentrate from the mill was received by the AEC in December 1957. In February 1962, TEC was fully merged into the Union Carbide Corporation, which assumed the TEC rights and obligations under the AEC contract. All uranium concentrate produced at the mill was sold to the AEC. Ore for the mill came from near-by open pit mines. In size, the ore deposits ranged up to 250,000 tons maximum. Output of ore from the open-pit mines varied from about 750 to 1,000 TPD of all grades. The average grade was about 0.20 percent U3O8, though the grade was highly variable, and economic ore was mined concurrently with large tonnages of low grade ore. The mine output was classified into four storage categories that ranged from mill-grade ore (at least 0.13 percent U3O8) down to waste rock (less than 0.02 percent U3O8). Over the years 1957-1964 under three AEC contracts, the mill processed nearly 1.8 million tons of ore that averaged 0.13 percent U3O8. The mill was operated at a throughput rate of about 700 tons per day (TPD), and its average uranium recovery rate was 88 percent. The mill was unique in that it used an upgrader circuit to treat low-grade ores before leaching. Low grade ore (containing less than 0.20 percent U3O8) was treated in the upgrader circuit that separated the uranium-bearing slimes from the sand fraction, which was rejected to the tailings pile. The slimes fraction was then acid leached. Higher grade ore was treated directly by acid leaching. The leached slurry passed through a classification/washing circuit that used parallel spiral classifiers and cyclones to separate the fine-grained slurry containing the uranium. This slime product was combined with the leached slimes from the upgrader circuit before entering ion exchange (IX) circuit. The resin-in-pulp ion exchange circuit consisted of six adsorption stages and ten elution stages. The continuous, countercurrent resin-in-pulp process was the first application of this technology in the domestic industry. Uranium was washed from loaded IX resin using ammonium nitrate solution and was precipitated directly with anhydrous ammonia. The coarse fraction from both circuits went to tailings storage. When the mill facility was closed down in October 1964, about 2.6 million tons of mill tailings remained at the site in a pond covering some 80 acres. In the late 1970s, UCC began heap leaching of the remaining low grade ore pile stockpiled at the site. A portable ion exchange plant was used at the site to collect the uranium from the heap-leach solution. The plant eluate product was trucked to the firm’s Gas Hills uranium mill for final processing. By 1982, the mill was dismantled, and the tailings pile was contoured and stabilized with a 6-inch covering of soil that was seeded with native grasses.

2 files, last one added on Jan 24, 2006

Album viewed 328 times

|

|

|

|

Mexican Hat Mill

|

|

|

|

Location: The former Mexican Hat uranium mill site is located on Navajo Nation land 1.5 miles southwest of Mexican Hat, San Juan County, Utah. The site is northeast of the town of Halchita, Utah, which began as the housing area for the mill's employees.

Background: Radioactive mineral deposits in the Triassic rocks of the Colorado Plateau area of Utah were first worked during the early 1900s. In 1912, a high grade vanadium-uranium deposit was mined in the Temple Mountain area of Emery County, Utah. During World War I, high grade uranium ore was mined for radium from deposits in the Chinle Formation (Moss Back Member) at Temple Mountain. Over the period 1920-1940, the U.S. Geological Survey conducted a field reconnaissance and mapping project to evaluate the oil and gas potential in a broad area of eastern Utah and northeastern Arizona. In that study, uranium, vanadium, and copper minerals in Triassic rocks were noted in many places throughout the region, especially near the unconformable contact between the Moenkopi Formation (Early and Middle(?) Triassic age) and the Chinle Formation (Late Triassic age).

From the early 1930s through 1945, several radioactive deposits in the region were mined principally for vanadium. The large vanadium-uranium deposit (discovered in 1921) in the Monument Valley area of northeastern Arizona was mined for vanadium in 1942. In about 1944, a few carloads of copper-uranium ore were mined from the Happy Jack mine in the White Canyon district and shipped to the Garfield smelter in Salt Lake County, Utah. From 1949-1953, the Vanadium Corporation of America operated a small mill near Hite, Utah, to process uranium ore from the White Canyon area (see the White Canyon Mill page). From the late 1940s through the 1980s, about 130 uranium mines were developed on the uranium deposits in the White Canyon-Red Canyon district. Most yielded less than 10,000 tons of ore, but four deposits contained more than 100,000 tons and one contained more than 600,000 tons of ore.

The White Canyon-Red Canyon uranium district in southwestern San Juan County lies along the western flank and crest of the Monument Upwarp, an uplifted region where sedimentary rocks of Permian to Jurassic age are exposed in the major stream canyons that formed along the upwarp‘s axis. In the district, which is about 40 miles long by 20 miles wide, uranium-bearing strata are present in the Shinarump Member, the basal Chinle Formation. Most of the minable uranium deposits in the Triassic rocks occur stratigraphically near the Moenkopi-Chinle unconformity. The uranium ore deposits are irregularly distributed and occur in Shinarump sandstone and conglomeratic strata that fill stream channels and scours that were eroded in Middle Triassic time into the underlying sandstone-siltstone strata of the Moenkopi Formation. Shinarump channels locally are deep and some cut through the Moenkopi and into the underlying Permian strata. Uranium present in the uppermost Moenkopi strata was locally mined where contiguous ore was present in overlying Chinle rocks. The ore deposits are generally tabular in shape and elongated with the trend of the hosting paleochannel strata. In most uranium deposits, the grade of the mineralization varies strongly over short distances, and adjacent deposits within the same channel commonly are separated by barren rock. The ore grade in mined deposits averaged between 0.20 and 0.30 percent U3O8, with some deposits also containing up to 2 percent V2O5 and other deposits up to 2 percent copper.

In July 1954, the U.S. Atomic Energy Commission (AEC) announced it would open a uranium ore-buying station in the White Canyon area of Utah near the Happy Jack mine. The station was opened in August 1954, and through July 1957 about 180,000 tons of ore containing some 916,000 pounds of U3O8 were purchased by the AEC and stockpiled at the buying station.

On July 17, 1956, the AEC contracted with Texas-Zinc Minerals Corporation for a mill to produce uranium concentrate through March 31, 1963. Texas-Zinc Minerals selected a mill site located on land belonging to the Navajo Nation, and the firm acquired a lease for the site and built the Mexican Hat mill. The mill opened in November 1957 with an initial capacity of 775 tons of ore per day (TPD). In 1958, the mill's throughput capacity was increased to 1,000 TPD. In August 1958 the AEC contract was modified to extend the final concentrate delivery term to February 1967. The modified contract also provided for the sale to Texas-Zinc of the AEC's stockpile of uranium ore at the White Canyon ore buying station. In June 1963, the mill and mill-site lease were acquired by the Atlas Corporation. Texas-Zinc's contract with AEC was terminated, and uranium concentrate remaining to be delivered to AEC was consolidated into the AEC-Atlas contract under which Atlas was operating its Moab, Utah, uranium mill. AZ Minerals, the new Atlas subsidiary, took over and continued to operate the Mexican Hat mill. From 1953-1965, the mill processed nearly 2.2 million tons of ore that averaged 0.28 percent U3O8. Mill feed came from independent ore producers (65 percent), mines controlled by Texas-Zinc and Atlas (25 percent), and from the purchased AEC stockpile (10 percent)1. The mill ceased operations in February 1965. Over its operating life, the mill achieved an average ore processing rate of 850 TPD and an average uranium recovery rate of more than 93 percent. All uranium production, about 11.4 million pounds U3O8, was delivered to the AEC. The mill was closed in early 1965. An on-site sulfuric acid plant that had supplied acid for the milling operation continued to be operated until 1970. When the mill-site lease expired in 1970, control of the mill site, including its buildings and tailings piles, reverted to the Navajo Nation.

The ore processed at the Mexican Hat mill contained sulfide copper and other sulfide minerals. Froth flotation was used to recover copper minerals from the finely ground ore fed to the mill. Flotation concentrates and tailings were separately acid leached. Leached copper concentrates were then filtered to obtain the final copper product. The copper-leach filtrate was combined with the main-circuit-leached tailings slurry (containing the bulk of uranium in solution). This uranium-pregnant liquor was separated from the leach solids by countercurrent decantation, and the liquor was clarified by pressure filtration. Uranium was recovered in a solvent extraction circuit that used centrifugal contactors. The final uranium oxide product was precipitated by neutralization of the ammonium nitrate strip solution with magnesium hydroxide. The uranium precipitate was thickened, washed, dried, and packed. The mill's copper-concentrate product was shipped to a smelter for processing.

4 files, last one added on Apr 30, 2006

Album viewed 431 times

|

|

|

|

|

Monument Valley Upgrader (Monument 2 Mine)

|

|

|

|

Location: The former Monument Valley upgrader site is on Navajo Nation land in Cane Valley, Apache County, Arizona, about 20 miles south of Mexican Hat, San Juan County, Utah.

Background: The Monument Valley uranium district is in the southern part of the Monument Upwarp, a north-trending, broad asymmetrical anticline (fold structure) in northeastern Arizona and southeastern Utah. The Upwarp's thick cover of fluvial and eolian strata has been deeply eroded to expose principally sandstone and shale of Permian, Triassic, and Jurassic age. Nearly all known uranium deposits in the district occur in fluviatile conglomerate and sandstone beds of the Shinarump Member, the basal unit of the Chinle Formation (Late Triassic age). The Shinarump was deposited on the Moenkopi Formation (Early and Middle(?) Triassic age). Throughout the southeastern Utah region, the two rock units are separated by the Middle Triassic unconformity. The individual paleostream channels eroded channels into the underlying Moenkopi beds can be up to several hundred feet wide and more than 100 feet deep. These channels are filled with coarse sediments that locally host uranium deposits, typically in "trashy," cross-bedded, conglomeratic, clayey sandstone with considerable fossilized and carbonized wood.

Uranium ore occurs in the Shinarump scattered at various levels. Ore is also present locally in the upper few feet of the Moenkopi and De Chelly Member (Early Permian) beds where either unit and the Shinarump ore-bearing channel strata are in contact. Ore bodies are generally elongate, lenticular, and follow the trend of the hosting paleochannel strata. The ore occurs mostly in smaller channels but is not known to completely fill any channel. Most ore bodies are about 100 by 50 feet horizontally and average about 5 feet in thickness, though some larger deposits range up to 20 feet in thickness. Uranium mineralization tends to be concentrated in high grade pockets associated with carbonized woody trash, the whole being surrounded by sub-ore grade to sparsely mineralized rock. The uranium-bearing ores in the Shinarump beds are described, based on metal content, as either vanadium-uranium ore, copper-uranium ore, or uranium ore containing minor amounts of vanadium and copper.

In the Monument Valley district, ore production from individual mines ranged from a few tons of ore to near 800,000 tons. For the district, the median production for 54 mines was about 25,300 tons of ore that averaged 0.32 percent U3O8 and 0.91 percent V2O5. The Monument 2 mine was a large vanadium-uranium ore deposit hosted by Shinarump strata that filled a large and deep erosional swale in the unconformity surface atop the Moenkopi Formation. At the mine, Shinarump channel beds are several hundred feet wide and extend for about 1.3 miles along the axis of the swale. A small amount of ore was reportedly mined for vanadium in 1943 from the Monument 2 mineral claim, first staked in 1942. Large-scale mining of the deposit for uranium ore was begun in early 1948 by Vanadium Corporation of America (VCA). In the mid 1950s, underground methods were used to mine pods of higher grade ore through multiple (about 15) short adits or shafts. Overall underground ore production averaged 125 tons of ore per day (TPD). Lower grade and higher grade ores were blended to maintain a minimum-grade, direct-shipping ore containing about 0.30 percent U3O8 and 1.40 percent V2O5. In this phase of mining the Monument 2 deposit, the ore was shipped 185 miles to the company's mill at Durango, Colorado.

In June 1954, stripping operations were begun for openpit mining at the south end of the Monument 2 deposit. Both the underground mines and openpit mine continued to produce until the summer of 1957, when underground mining ended. Openpit operations were continued until the mine was closed in June 1964. The open-pit mine average production rate was about 750 TPD. In its early years, the openpit yielded both higher grade ore along with considerable low grade ore. Later, the openpit yielded only low grade ore. Mined high grade ore was shipped directly to a mill, while low grade ore was stockpiled onsite for later processing to concentrate the uranium and vanadium values. An upgrader plant (1955-1964), a batch-leach plant (1964-1967), and a heap-leaching operation (1966-1967)were used to raise the mine-run, low grade ore to a shipping grade product. All U3O8 recovered from milling of the final products obtained from the upgrader, batch-leach, and heap-leaching plants was purchased by the U.S. Atomic Energy Commission (AEC).

1 files, last one added on Jan 24, 2006

Album viewed 336 times

|

|

|

Naturita Mill

|

|

|

|

Location: The Naturita mill site is located two miles northwest of Naturita in Montrose County, Colorado, in the narrow, steep-walled canyon of the San Miguel River.

Background: Built about 1930 by the Rare Metals Company, the mill was first operated in 1939 after being purchased and rebuilt by the Vanadium Corporation of America (VCA). The mill produced a uranium-vanadium sludge (1942-1946) that was sold to the Manhattan Engineering District (MED), Army Corps of Engineers. At that time, old vanadium mill tailings from the Naturita site were also sold to MED for uranium recovery at the Government-owned Uravan, Colorado, mill. The U.S. Atomic Energy Commission’s (AEC) first uranium procurement contract was with VCA in May 1947. From 1947-1958, the mill processed ore that averaged 0.30 percent U3O8 and 1.68 percent V2O5. The ore came from small underground mines in the Uravan mineral belt area of Colorado and Utah. Ore-processing recovery rates at the mill averaged only 77 percent for uranium and 68 percent for vanadium, resulting in higher than usual residual metal values remaining in the mill tailings. The mill was shut down in1958. VCA continued to receive uranium-vanadium ores at the mill site after the shut down, and the company constructed an upgrader plant on the site in 1961 to treat that ore. The upgrader products (ore slimes and uranium and vanadium precipitates) were shipped for processing to other VCA mills, mainly the VCA mill at Durango, Colorado. When the upgrader plant was shut down in 1963, the remaining Naturita mill buildings and the upgrader were dismantled. In 1967, VCA merged with the Foote Mineral Company, which became the new mill site owner. General Electric leased a portion of the mill site in 1975 for use as an ore-buying depot. In 1976, Ranchers Exploration and Development Corporation (later acquired by Hecla Mining Company) purchased the Naturita tailings pile for its high residual metal values. In 1977-1979, Hecla moved the mill tailings to its Durita site where the tailings were reprocessed to recover the residual high uranium and vanadium values. Ranchers then covered and stabilized the relocated, reprocessed tailings according to Colorado Department of Health regulations. In 1996, the old Naturita mill site consisted of the original 53-acre mill site with residual radioactively contaminated soil and remaining mill structures plus 85 adjacent acres contaminated by wind-blown and water-borne mill-tailings materials from the mill site.

3 files, last one added on Jan 24, 2006

Album viewed 386 times

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rifle Mills (Old and New)

|

|

|

|

Location: The Rifle (Old and New) Mill sites are located near the town of Rifle in Garfield County, Colorado.

Background: The Old Rifle mill was situated on a 24-acre parcel on the north side of the Colorado River about 0.3 miles east of Rifle, Colorado. The plant was built by the Standard Chemical Company in 1924 and operated until 1928. In the early 1920s the domestic radium industry collapsed, and domestic uranium-vanadium ores were treated mainly for vanadium recovery. The uranium values were discharged along with the mill tailings. The United States Vanadium Company purchased the Rifle plant in 1928 and used it to recover vanadium from roscoelite ore until 1932, when an ore shortage forced its closing. In 1942, Union Carbide Corporation (UCC, which had acquired U.S. Vanadium and the mill) reactivated the mill for vanadium production in support of the war effort. In 1947, the Atomic Energy Commission signed the first of four contracts with UCC for uranium procurement, and the milling process was modified to allow recovery of uranium and vanadium by a sulphuric and hydrochloric-acid leaching process. From October 1947-December 1957, the Old mill processed ore at about 200 tons of ore per day (TPD) and treated nearly 0.7 million tons ore averaging 0.35 percent U3O8 and 1.59 percent V2O5. The mill’s raw ore feed came mainly from company-controlled mines and independent miners in western Colorado. Old vanadium tailings remaining on the site from earlier operations were reprocessed at the mill to recover uranium and residual vanadium. From the combined mill feed materials (ore and tailings), uranium recovery averaged 85 percent and vanadium averaged 69 percent. The AEC purchased all U3O8 produced and 27 percent of the V2O5 during the AEC-contracts period (1947-1957). Of the 0.7 million tons of tailings generated during the AEC uranium contracts period, about 0.4 million tons eventually were moved to the New Rifle mill and reprocessed for uranium and vanadium. The remaining tailings pile, about 0.3 million tons, stood about 33 feet tall and covered 13 acres at the old mill site. In 1967, UCC stabilized the tailings pile in accordance with the State of Colorado regulations. At that time, the pile was reshaped, covered with a 6-inch layer of soil, and seeded with native grasses. The Old Rifle Mill continued to operate during the period of construction of the New Rifle Mill.

The New Rifle Mill was built on a 300-acre parcel located about 2 miles west of Rifle just north of the Colorado River. It began operation in January 1958 at a nominal capacity of 400 TPD. Mill feed consisted primarily of ore from both company-controlled mines and independent miners in western Colorado plus uranium concentrate (slimes and chemical precipitates) from UCC's upgrader plants located at Slick Rock, Colorado, and Green River, Utah (1957-1961), lignite-ash product from the Belfield, North Dakota, ashing facility (1965-1967), and other tailings and residue materials. The new Mill produced uranium concentrate for sale to the AEC through December 1970. During the period of AEC contracts, the mill averaged 400 TPD throughput and treated a total of 1.8 million tons of ore that contained 8.4 million pounds U3O8 and 76.7 million pounds V2O5. Other mill feed, upgrader ore concentrates, lignite ash, tailings, and residues, contained an additional 4.5 million pounds U3O8 and 65.4 million pounds V2O5. Over the years 1958-1970, recovery from the combined mill feed averaged 90 percent or uranium and 83 percent for vanadium. About 96 percent of the uranium concentrate from the mill was purchased by the AEC. All of the mill's vanadium production was delivered to the commercial market. At the termination of UCC's last AEC-procurement contract (December 1970), there were about 2.5 million tons of tailings impounded at the New Rifle Mill site. The mill continued to produce uranium during 1971 and 1972 for the commercial market. At that time, the tailings pile at the new mill site contained about 2.7 million tons of tailings in two piles that covered an area of about 32 acres and stood about 65 feet above the surrounding site. From 1973-1984, the vanadium circuit at the mill was used to treat vanadium solutions trucked from UCC's mill at Uravan, Colorado. This vanadium recovery operation did not result in the addition of tailings to the existing tailings pile. Prior to 1982, UCC had covered the tailings piles with soil and had seeded, fertilized, and irrigated them to stabilize the steep slopes by establishing a vegetative cover. This was only partly successful, and the piles eventually were impacted by wind and water erosion.

1 files, last one added on Jan 24, 2006

Album viewed 322 times

|

|

|

|

Riverton Mill

|

|

|

|

Location: The site of the former Riverton uranium-vanadium ore processing mill is located about one mile southwest of the city of Riverton, Fremont County, Wyoming. The mill site and tailings pile were situated on privately owned land that is located within the boundaries of the Wind River Indian Reservation.

Background: The Wyoming Basins region is a part of the Rocky Mountain province and consists geologically of high mountain ranges separated by synclinal basins that form broad valleys between the ranges. Most of the uranium deposits in the Wyoming basins are hosted by sedimentary rocks of Tertiary age. The mountain ranges are mainly breached anticlinal structures where Precambrian granitic-rock cores were exposed by erosion during the waning stages of the Laramide orogeny.

Uranium occurrences are widely scattered across the region. During World War I, uranium ore was mined for radium from a vein deposit at the Silver Cliff mine in the Hartville uplift area near Lusk, Wyoming. Though other deposits were reportedly known in the region, none was exploited before the mid 1950s. In 1951 while conducting field work, J. D. Love, U.S. Geological Survey, discovered uranium minerals on outcrops near the Pumpkin Buttes area of the Powder River Basin, Wyoming. In 1953, Neil McNiece, prospecting along the Beaver Rim in the Gas Hills area east of Riverton, Wyoming, found uranium on outcrops of the Wind River Formation (early Eocene) above the Lucky Mc claims. These developments kindled further exploration efforts that soon led to other discoveries. Subsequent airborne radiometric surveys by the U.S. Atomic Energy Commission (AEC) and follow-on surface drilling by private industry resulted in the discovery and development of ore deposits in the Gas Hills district. Exploration rapidly spread to areas in other basins, and by 1954 uranium occurrences had been found in all areas of the Wyoming Basins region. By 1956, the deeper-lying, large unoxidized uranium ore deposits had been discovered in the central Gas Hills area in the coarse arkosic sandstone and conglomerate beds in the upper part of the Wind River Formation. Of the 70 mine properties that had been developed in the district through 1990, 16 had each produced more than one million pounds of U3O8 and six properties had each produced more than one million tons of ore. The Gas Hills district is located along the south central edge of the Wind River Basin near the northern border of the Granite Mountains-Sweetwater Arch.

Uranium was discovered in the Big Pryor Mountains area of southern Montana in September 1955 and in the Little Mountain area of Wyoming in early 1956. The deposits occur in the Madison Limestone (Missippian age) which in the upper 200 feet contains an extensive system of solution caverns. Some caves are filled with insoluble breccia and silty debris. Locally, the cave-filling and permeable zones within the limestone contain uranium and vanadium mineralization. The caves vary widely in size and most are barren. Ore produced from 20 mines averaged 0.36 percent U3O8 and 0.38 percent V2O5. The median mine yield was about 250 tons of ore, but two mines produced more than 5,000 tons of ore. The ore's erratic character, excessive distance to the closest mill, milling penalties due to the ore's high lime content (usually above 70 percent CaCO3), and the declining grades of mined ore over time caused operations to close by 1966.

In November 1954, the U.S. Atomic Energy Commission (AEC) leased a site southwest of Riverton, Wyoming, from the Chicago & North Western Railway Company for a uranium-ore buying station. AEC operated the buying station from March 1, 1955, to late 1957. Some 152,700 tons of ore averaging 0.23 percent U3O8 were purchased and stockpiled at the site during that period.

In December 1957, the AEC entered into a contract for the purchase of uranium concentrate from a mill at Riverton, Wyoming. The initial contract was with Fremont Minerals, Inc., a subsidiary of Susquehanna-Western, Inc. (SWI). In January 1961 the Fremont contract was replaced when the AEC and SWI entered a new contract for which the term extended through December 31, 1966, with final concentrate deliveries scheduled February 1967. The prime purpose of the Riverton mill was to provide a market for ore and uranium from the increasing number of uranium mining operations then emerging in the Gas Hills, Pryor-Little Mountains, and Wind River Basin areas. Most of the ore treated at the Riverton mill, which was operated as a "custom" mill from November 1958 until May 1963, came from mines in the Gas Hills area. After the mill was shut down in June 1963, SWI shipped uranium ore from company mines and ore purchased from independent miners to the Federal-American Partners' uranium mill in the Gas Hills district. The AEC continued until July 1965 to purchase the uranium concentrate produced under the SWI-Federal toll-milling arrangement.

2 files, last one added on Apr 30, 2006

Album viewed 320 times

|

|

|

|

|

|

Salt Lake City Mill

|

|

|

|

Location: The Salt Lake City mill site, known also as the Vitro mill site, is located south of Salt Lake City, Utah, within the metropolitan area.

Background: In 1951, Vitro Corporation of America purchased the old Kalunite Plant that had produced alumina from Utah clays during World War II. Vitro converted the plant to a sulfuric-acid leaching process for treating uranium ore, and it became known as the Salt Lake City mill. From May 1952 to January 1964, the mill shipped uranium concentrate under three procurement contracts to the U.S. Atomic Energy Commission (AEC). The old alumina plant’s ore roasters were retained, and uranium ores with high carbonaceous content were roasted to improve the ore processing characteristics. The initial uranium milling process included acid leaching of the ore, countercurrent decantation, and precipitation of a uranous-phosphate product. During 1957, the mill was converted to a unique solvent extraction process that also permitted the recovery of small quantities of byproduct scandium. The mill’s initial capacity of about 100 tons of ore per day (TPD) was expanded several times, so that by 1957 milling capacity was 600 TPD. Over the AEC contract years, the mill processed about 1.7 million tons of ore and produced nearly 9.6 million pounds U3O8. All but a few pounds of the U3O8 product was sold to the AEC.

The Salt Lake City mill was operated mainly as a custom mill. Most of the ore processed was received from independent mines in southeastern Utah, though ore was also received from mines in several western states. From 1953-1958, uranium ore purchased under an AEC’s ore-buying program was stockpiled at the mill site. The AEC-purchased ore, along with ore from other AEC buying stations in the Utah region, was later sold to Vitro and processed at the mill. The uranium ore processed at the mill from 1953-1955 contained appreciable vanadium (averaging 0.7 percent V2O5), but it was not recovered during the years in which the mill supplied uranium to the AEC. When the mill was closed in 1964, the uranium ore remaining at site (about 58,000 short tons) was sold to the Atlas Corporation and transported to the latter’s mill at Moab, Utah. After uranium production was phased out, Vitro converted the Salt Lake City mill to recover vanadium by processing a waste product obtained from an elemental phosphorus production plant in Idaho. The Salt Lake City mill site was permanently closed in 1968. From its uranium ore processing, the Salt Lake City mill generated about 1.7 million tons of tailings. When the mill was closed down in 1968, the sites two piles held about 2.6 million tons of tailings material. Clean up of the mill site was begum in 1968. By 1970, the mill structures were demolished except for a 450-foot tall stack, a railroad spur, and a water tank. Radioactively contaminated soil and was excavated and shipped to other mills.

5 files, last one added on Jan 24, 2006

Album viewed 403 times

|

|

|

|

|

|

|

Shiprock Mill

|

|

|

|

Location: The former Shiprock mill site is located on the southwest side of the San Juan River and adjacent to the town of Shiprock in San Juan County, New Mexico. The tract of land on which the former mill was located was leased from the Navajo Nation.1

Background: The Shiprock mill processed mainly uranium-vanadium ore from mines located in the Carrizo Mountains, Lukachukai Mountains, and Sanostee Wash areas in northeastern Apache County, Arizona, and adjacent San Juan County, New Mexico, all on Navajo Indian Reservation land. It processed uranium-vanadium products from the Monument Valley upgrader-plant in northeastern Arizona as well as uranium ore from the Velvet Mine, Lisbon Valley district, Utah, and some Poison Canyon mines, Grants district, New Mexico. The Shiprock mill also processed uranium ore from mining districts in western Colorado, after the Durango, Colorado, mill was closed in 1963.

The host rocks for vanadium-uranium deposits in the Four Corners area of northeastern Arizona and northwestern New Mexico are principally sandstone beds of the Salt Wash Member (Morrison Formation, Upper Jurassic). In surface exposures around the Carrizo Mountains, the Salt Wash host rocks are intruded and bowed upward by the Tertiary age igneous rock that was injected as an irregularly shaped, central mass in the mountains and as sills that extend laterally into the sedimentary sequence around the mountains. About 15 miles south of the Carrizo Mountains, the Lukachukai Mountains form a high ridge that extends northwestwards from the Chuska Mountains. Below the crest of the Lukachukais, folded and truncated Salt Wash host rocks are exposed on finger-like “mesas”carved by erosion into the northeast and southwest mountain slopes. Salt Wash strata in the Lukachukai are unconformably overlain by about 700 feet of Tertiary age eolian sandstone that also forms the flat-topped mountain summit.2

In 1918, vanadium-uranium mineralization was discovered on Salt Wash sandstone outcrops exposed on the slopes of the Carrizo Mountains. In the northwest Carrizos area, 20 tons of uranium-bearing radium ore was shipped in November 1920 from a lease owned by Radium Ores Company.3 From the mid 1920s until the mid 1930s, vanadium-ore mining decreased in the Carrizo Mountains area.4 In the mid to late 1930s, however, vanadium mines were being reopened in southwestern Colorado and southeastern Utah.

By 1941, high demand for domestic vanadium for manufacturing of hardened steel for the war effort led to increased mining of vanadium ore in the Carrizo Mountains area. Under a program to study critical materials for the war effort, in late 1942 the U.S. Geological Survey mapped the vanadium mines, compiled data on vanadium production, and prepared estimates of the vanadium resources. The results of the project were given to the Manhattan Engineer District.5

Between 1942-1945, about 21,300 tons of ore containing about 1.0 million pounds V2O5 was shipped from the Carrizo Mountains area. The ore was processed at the Monticello, Utah, and Durango, Colorado, mills.6 The vanadium ore also contained about 108,600 pounds of U3O8.7 When the Manhattan Project was created in August 1942 under the Army’s Corps of Engineers, acquisition of uranium raw materials for weapons production was a key function. It has been estimated that during 1943-1945 some 76,000 pounds U3O8 was secretly recovered from the Carrizo vanadium-uranium ores processed at the Monticello, Utah, and Durango, Colorado, mills for the Manhattan Project for use in the atomic weapons program.

In 1943, Union Mines Development Corporation, under contract to the Manhattan Engineer District, began a field program to study and map carnotite-bearing prospects and mines in outcrops of the Salt Wash Member on the Colorado Plateau.10 In the fall of 1943, a field party investigated Salt Wash outcrops in the southern Carrizo Mountains, Arizona. By December that year it had moved south onto Mexican Cry Mesa, the northernmost of the Lukachukai “mesas.” By the end of the 1943 field season, only small and widespread uranium-vanadium occurrences had been found on the mesa. Field work was not resumed in the Lukachukais the following year, because it was thought that further south into the mountains the Salt Wash Member had been removed during a period of erosion that preceded deposition of the Tertiary sandstone that caps the mountains. The uranium-bearing Salt Wash outcrops in the Lukachukai uranium-ore belt thus were not discovered until early 1949.11

Vanadium demand declined sharply in 1944.12 From 1945 to 1947 fewer shipments of vanadium-uranium ore were made from mines in the Carrizo Mountains area.

The U.S. Atomic Energy Commission (AEC) was established January 1, 1947, and assigned the functions of uranium studies and uranium procurement for the Federal Government. Under the AEC, several events in 1948 and the early 1950s influenced uranium development in the northeastern Arizona and northwestern New Mexico region. In April 1948, AEC issued the Domestic Uranium Program Circular 3 that provided minimum prices, specifications, and conditions for AEC to purchase different types of uranium ore delivered at the Monticello, Utah, ore-buying station.13 With the sale of mined ore guaranteed, exploration for uranium intensified across the northeastern Arizona and northwestern New Mexico area. Mines controlled by Vanadium Corporation of America (VCA) on the East and West Reservation Leases in the Carrizos were reopened in 1948 and the uranium-vanadium ore was shipped to VCA’s Naturita, Colorado, mill. In 1949, the AEC contracted with VCA to mine a lease on Cove Mesa it had acquired from Union Mines Development Corporation.14

Early in 1949, a prospector working with two Navajo men reported finding uranium minerals on sandstone rim outcrops in the Lukachukai Mountains. Under tribal law, a mining permit could only be issued to a member of the Navajo Tribe, who was then free under Tribal regulations to assign the mining rights. The men applied for mining leases to the Navajo Tribal Council in May 1949. After completing an engineering survey of the discovery areas, leases were issued to the two men by the Department of Interior in December 1949. The leases covered about 1.8 square miles in six parcels located on mesas along the northeast and southwest sides of the Lukachukai Mountains. On the day when the leases were issued, the men assigned a 75 percent interest in their leases to F.A. Sitton, a private firm. Sitton built two dirt-surfaced roads in 1950 from Cove, Arizona, into the high Lukachukais to access the separate lease areas. The first ore shipment from the Lukachukais was in June 1950 to VCA’s mill at Durango, Colorado. Other ore shipments that year went to the AEC uranium ore-buying station at Monticello, Utah.

Between September 1950 and August 1955, the AEC conducted six exploratory drilling projects in the Lukachukai Mountains area. Geological and uranium mineral-occurrence data developed by the drilling projects were placed on an open file by the AEC. The data aided the mining companies in developing additional minable uranium ore reserves.15

In March 1951, Sitton applied to the Navajo Tribal Council to lease a 160-acre tract near Shiprock, New Mexico, for construction of a 100 ton-per-day uranium mill. The lease was approved, But the proposal to build the uranium mill was not approved by the AEC.

Early in 1951, Climax Uranium signed an agreement covering the operation of uranium mines in the Lukachukais for a Navajo lease holder. Climax built an access road up to deposits in the northern part of the uranium ore belt area. The first ore shipment from that area was made in June 1951 to the AEC ore buying station at Monticello, Utah. Other miners also shipped ore out of the Lukachukais using the Climax-built road.

A private effort was begun in summer 1951 to map and sample mineral occurrences in the Salt Wash Member in the ore belt area on the northeastern face of the Lukachukais. The results of the study showed excellent potential for additional ore to be developed in that area. In August 1951, the newly formed Navajo Uranium Company (NUC) of Cortez, Colorado, acquired the F.A. Sitton, Inc., firm and the leases it held by assignment. Data from the new study along with the positive results from the AEC’s exploratory drilling program prompted the NUC to propose a 300 ton-per-day mill at Shiprock, New Mexico. The proposed mill was not approved by the AEC; however, it did approve the building of an ore-buying station at Shiprock. The buying station was opened in January 1952 and was operated by American Smelting and Refining Company under contract to the AEC. The Shiprock station provided a market for all non-VCA controlled uranium ore mined in the northeastern Arizona and northwestern New Mexico areas.